The Data Layer

The M-DISC™ data layer is a nano-scale, multi-layer structure consisting of metals and other inorganic materials. It is substantially different from the conventional organic, dye-based DVD-R in that it was designed from the beginning to last for centuries without the failure points common to conventional DVDs. Oxidation of the nano-scale data layer in the M-DISC™ during long-term storage is the only potential cause of data loss that is a concern as long as the polycarbonate substrate survives.

The materials used in the M-DISC™ data layer are extremely resistant to oxidation. Even so, if enough oxidation occurs over the centuries, the M-DISC™ could still become unreadable at some point in time. Determining the maximum rate of oxidation is the key to determining the lifetime of the M-DISC™.

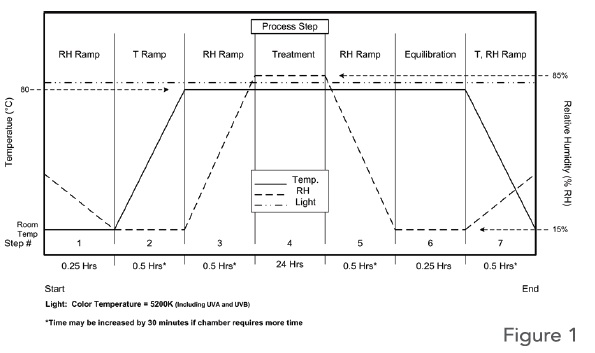

Measuring Longevity

Measuring M-DISC™ performance to directly determine the longevity is a challenge. When something changes very slowly, taking meaningful measurements requires a long period of time. The data layer is so resistant to oxidation that observable changes in an M-DISC™ stored under normal conditions are still barely detectable after months. One way to deal with this challenge is to make a worst-case estimate of the lifetime using well-known theories and data and then test the results against measured data to see if the estimate is useful. Oxidation of the metal layers is the probable failure mechanism. Theorists agree that the oxidation of metals like those used in the M-DISC™ proceeds logarithmically. The bare metal forms a thin, nano-scale oxide layer very quickly. This oxide layer then protects the rest of the metal layer from further oxidation. If this is the correct physical model for oxidation of the M-DISC™ data layer, the M-DISC™ reflectivity over time should look like the curve shown in Figure 1. Most of the change in reflectivity would occur in the first few months after the disc is manufactured.

Greater than 10,000 Years

A worst-case scenario for failure in the data layer would be a critical loss in reflectivity as the metals in the M-DISC™ slowly oxidize. Failure would occur when the reflectivity dropped below the minimum specification of 18%. Figure 1 shows the reflectivity curve we would expect to see due to oxidation if the M-DISC™ data layers reach a reflectivity of 18% after 10,000 years. The curve shows that if the M-DISC™ was readable for only 10,000 years, we would expect to see it lose more than 3% reflectivity after aging only 50 days. A 3% change is easily measurable. Of course, if the reflectivity changed at a slower rate, the M-DISC™ could be expected to last even longer. The actual observed reflectivity change is less than 1% after 300 to 350 days (as shown with the graph inset into Figure 1) indicating the actual performance of the M-DISC™ data layer is significantly better than our worst-case scenario. The obvious conclusion is the data on an M-DISC™ should be readable for greater than 10,000 years when stored in an ordinary, dry, room-temperature environment.

Polycarbonate: Stable for 1,000 Years

Since it is doubtful that the polycarbonate substrate materials can endure for that length of time, the

substrate materials must be the actual weak link in the M-DISC™ structure. Studies of the longterm

durability of polycarbonate concluded that the substrate materials in DVDs should be

reliable for at least 1,000 years. Therefore, a lifetime estimate of at least 1,000 years,

limited by the durability of the polycarbonate substrate, is very reasonable.

For additional information about this product line, please go to our M-DISC™ Information Page.

You can also view or download this information here.